Surface finish affects a machined part’s durability, performance, and appearance. A smooth finish can reduce friction and wear, allowing the part to operate more efficiently and last longer. High-quality finishes with tight tolerances also help optimize final product assembly by providing a precise fit.

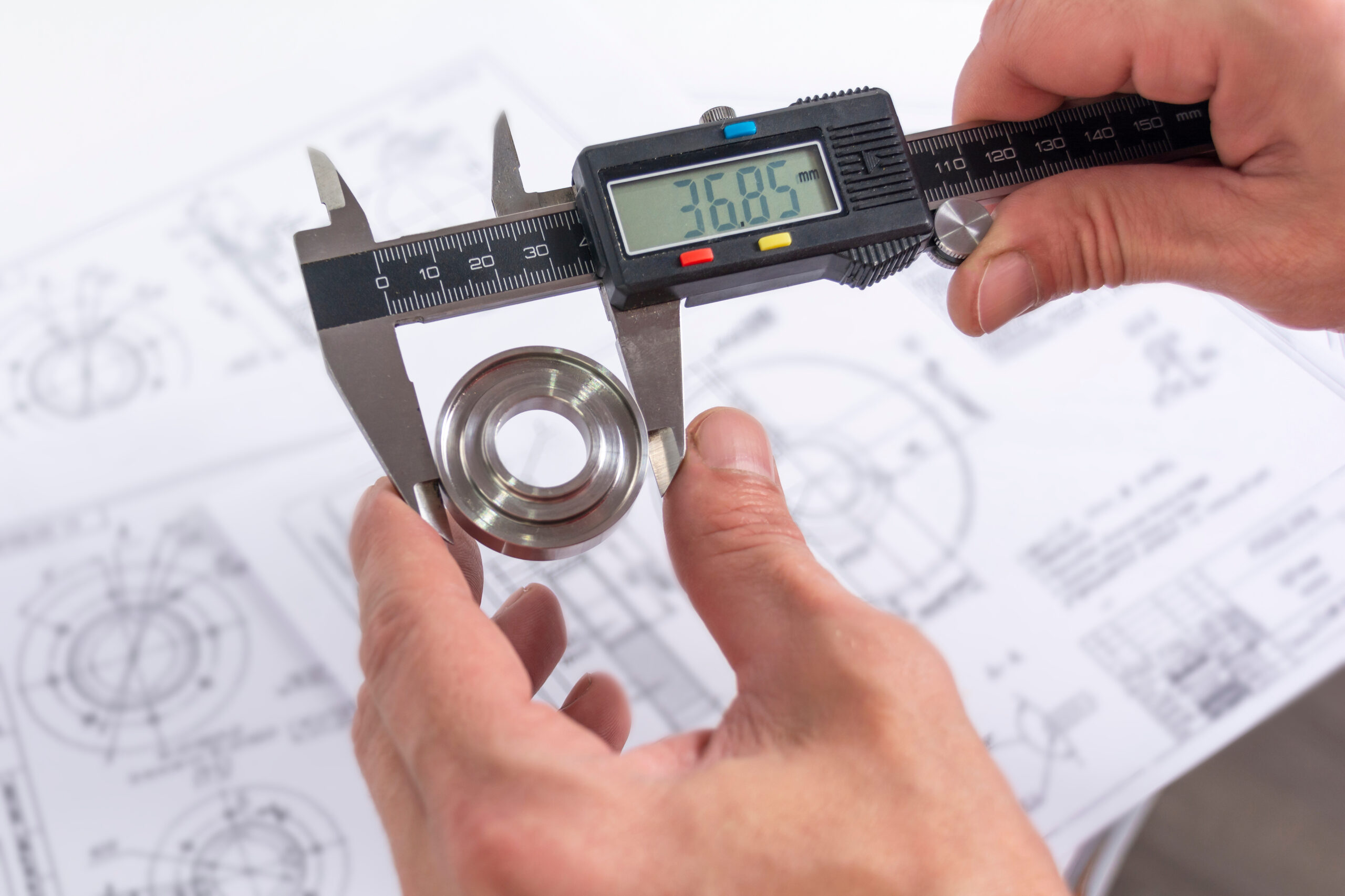

Understanding a machined part’s critical features and characteristics is essential in identifying the root causes of poor finishes and other quality problems. A critical characteristic is a feature or specification that is crucial to the quality of a machined part. These characteristics are referred to as “critical” because any deviation from the specified requirements could have a significant impact on the performance and quality of the final product.

Troubleshooting poor part quality during a machining process is vital because it directly affects a company’s operational success. Identifying the underlying factors early enough allows operators to make the required adjustments to improve a part’s critical characteristics and overall quality. Overall, addressing problem areas promptly helps decrease scrap, reduce reworks, and minimize downtime.

Producing high-quality machined parts involves evaluating many of the fundamentals of machining. While there are limitless factors that can affect product quality, some of the primary ways to troubleshoot poor part finishes include:

If a machine’s spindle shows signs of runout, vibration, noise, or other issues, Setco can provide the professional spindle repair services needed to remedy the problem. As the largest independent spindle rebuilder and manufacturer in the United States, we specialize in servicing and repairing over 350 machine tool brands. In addition, we can rebuild or repair machine slides to customized or OEM specifications.

Professionals globally recognize Setco products and services as the most accurate and reliable in the industry. Whether a customer needs us to install new bearings and seals, test the spindle motor, or reverse-engineer parts, we can accommodate their needs.

To learn more about how our products and services benefit machining applications, the experts at Setco can help. We walk customers through the most practical and effective solutions that meet their operational needs. Contact us online today to get started.