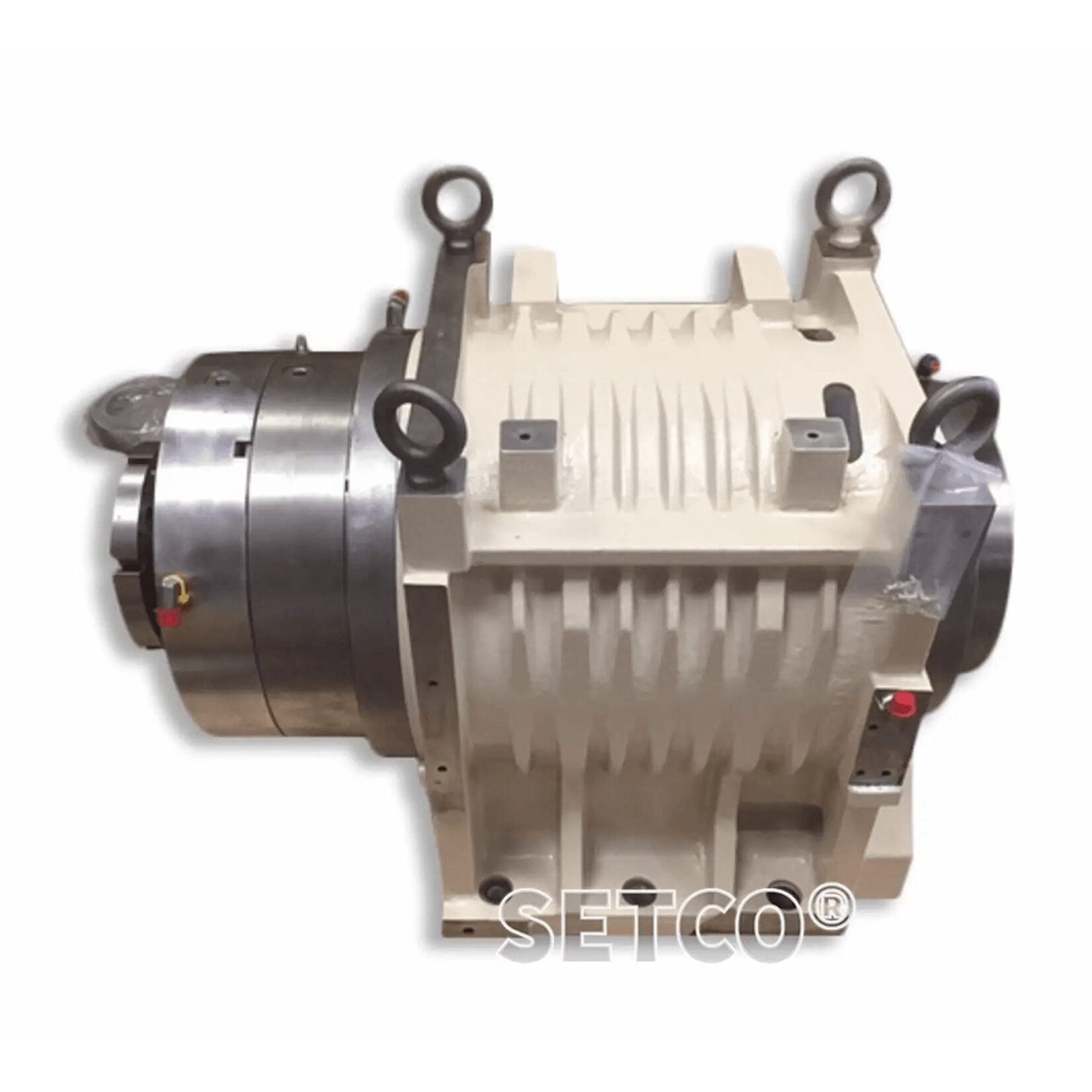

First, we separate the spindle parts and clean them. We then run a thorough analysis to identify the reason for failure and inspect parts to determine their condition.

We perform a rigorous testing process that entails:

- Determining whether the drawbar pull force meets OEM specifications.

- Verifying that the sensors and encoders produce an accurate signal.

- Checking motor parts for electrical shorts and insulation issues.

- Assessing bushings, spacers, bore, caps, bearing journals, and other parts for wear and tear and damage.

- Measuring tool connection surfaces, the shaft, and housing to determine fit and size problems.