Technicians take apart the spindle and thoroughly clean all parts. We inspect housing bores, taper surfaces, shaft journals, bearing races, and seals to determine the cause of the failure and identify components that require replacement.

Miyano has manufactured precision CNC equipment known for rigidity, accuracy, and high-volume production capabilities for decades. Now part of Citizen Machinery, Miyano produces fixed-headstock lathes, twin-spindle turning centers, and multi-axis machines that serve automotive, aerospace, medical, and general manufacturing industries. These machines rely on spindles for efficient, continuous operation under demanding conditions.

Setco is highly familiar with Miyano specs and stocks the specialized parts needed for proper spindle repairs. Our technicians have worked on hundreds of Miyano spindles and know the best repair practices for each type.

Miyano turning centers and lathes depend on spindle performance to accurately and efficiently produce parts. Worn bearings create runout that shows up as dimensional variations in turned parts. Seal wear allows cutting fluids and chips to enter bearing assemblies, leading to contamination and premature bearing failure.

Spindles that won’t hold bar stock securely or collets that slip during operation typically indicate spindle taper wear. Excessive heat buildup during normal cutting operations points to bearing preload issues or inadequate lubrication. Grinding or rumbling sounds during spindle rotation signal damage to bearings that requires immediate attention.

Failing to address these issues promptly can result in costly downtime, inconsistent finishes, incorrect dimensions, and potentially catastrophic damage to the machine.

Choosing Setco means enjoying various benefits, including:

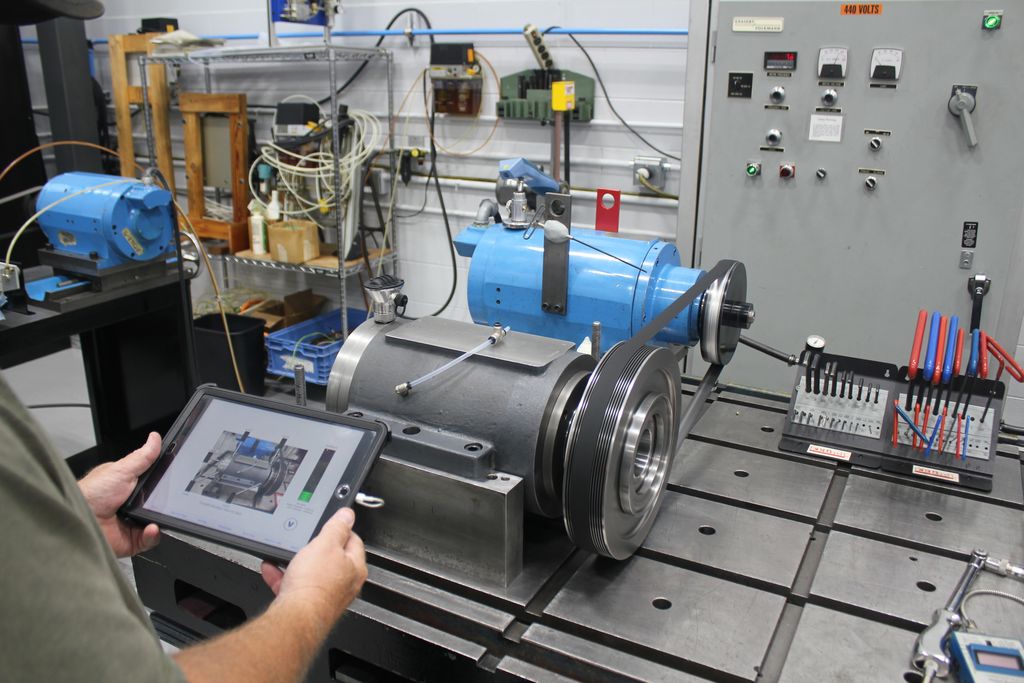

For Miyano spindle repairs, Setco follows a precise, multistep process to restore reliability and maintain peak operation:

Technicians take apart the spindle and thoroughly clean all parts. We inspect housing bores, taper surfaces, shaft journals, bearing races, and seals to determine the cause of the failure and identify components that require replacement.

Customers receive written estimates that break down necessary repairs and costs, with no surprise charges. The quote details exactly what work will be performed before we start.

Worn parts get replaced with quality components that meet OEM specifications. We machine housings to restore proper fits, refinish shafts with new cladding, install new bearings with correct preload, and replace all seals and electrical components when needed.

Rebuilt spindles run at full speed with thermal stabilization while we track vibration data and performance measurements. Testing continues until the spindle operates within specification at maximum rated speeds. All data gets stored by serial number for warranty purposes.

Finished spindles receive final inspection and ship with test results, parts lists, and warranty information.

Failing to address spindle problems in Miyano turning centers and lathes will eventually disrupt production schedules, compromise part quality, and lead to long-term equipment damage. Setco repairs these spindles with thorough testing and documentation to ensure optimal performance. Contact us online or call for a repair quote and evaluation.