When we receive a spindle, our technicians will disassemble it and clean the components. We’ll evaluate the spindle for failure to determine the origin of the failure.

The Chiron Group has over 100 years of experience designing and manufacturing precision technology and tooling, including spindles. Chiron spindles deliver flexibility, productivity, and precision for key industries like aerospace, stone cutting, friction stir welding, spin testing, grinding, food processing, and robotics.

Setco is your trusted partner for repairing Chiron spindles. Our technicians can identify the issues and make the necessary repairs to restore your spindle to operational condition.

A variety of issues can cause a Chiron spindle to fail. No matter the issue affecting spindle performance, Setco technicians can repair it right away, including:

Setco has been in the industry since 1912. Our experience, comprehensive service centers and repair machinery means we can service spindles from over 350 brands, including Chiron.

Our team has experience with many types of Chiron spindles, including:

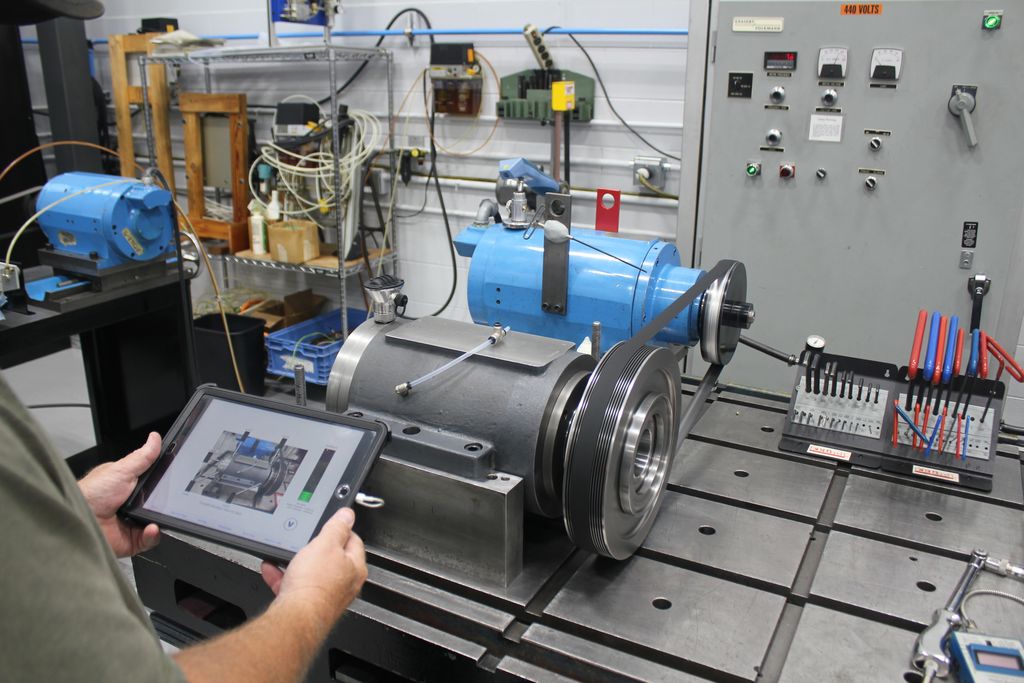

Our spindle repair and rebuild process is thorough to restore Chiron spindles to like-new performance. Our work is backed by our warranty protection and commitment to excellent service.

Our technicians will complete the following steps:

When we receive a spindle, our technicians will disassemble it and clean the components. We’ll evaluate the spindle for failure to determine the origin of the failure.

We’ll examine the components to identify improper fit and size, damage, and wear. Some parts we’ll inspect include bushings, bearing journals, spacers, caps, shoulders, bore, and more.

After assessing the repair work required, we’ll send a firm price quote, free of charge and without obligation. When you approve the quote, we’ll start the work. If you decline the quote, we’ll return the spindle immediately.

We’ll replace or recondition the broken parts to OEM specifications to return the spindle to like-new operation. Our technicians can replace spindle bearings, check electrical parts, replace spindle seals, sleeve and machine housings, replace drawbar seals, and more.

After all components have been inspected, cleaned, and reworked, our technicians will reassemble the spindle, precision balance it, and complete a full run off under controlled conditions until it is thermally stabilized at maximum speed. We’ll store the baseline vibration and testing data electronically by serial number.

After our technicians have rebuilt the spindle and it has passed all testing, we’ll return it. Setco also provides full documentation, certification, and a written warranty.

Choose Setco as your partner in Chiron spindle repair. You can trust our technicians, technology, and experience to provide professional repairs with a quick turnaround and long-lasting results.

Learn more about how we can service your Chiron spindles by calling your nearest location or contacting us online.