We carefully disassemble the spindle and check for damaged parts and components, wear and tear, and other signs of damage. We will also identify the causes of the issues to help us select the most practical repair methods.

Cincinnati spindles have an excellent reputation for reliability, performance, and quality in the most challenging manufacturing environments. As the world’s largest independent spindle rebuilder with more than a century of experience in the machine tool industry, Setco can meet all of your Cincinnati spindle repair needs.

We have the expertise, technology, and resources to restore equipment to original OEM specifications or better. We help companies in metalworking, aerospace, robotics, plastics, and many other industries maximize uptime and productivity by keeping their essential machinery on the job.

Several situations can indicate the need for spindle repairs. You may notice unusual noises, such as grinding, squealing, knocking, or rattling, while the spindle is operating. If there are excessive vibrations, it can lead to poor surface finishes and decreased accuracy. Other warning signs include visible damage like cracks and rust, overheating, and diminished performance.

Setco allows you to customize Cincinnati spindle repair by choosing from several spindle service levels:

At Setco, we have a legacy of innovation that gives us a competitive edge. Our ISO 9001:2015-certified facilities and global network of service centers ensure you receive consistent, high-quality spindle repair — no matter where you operate.

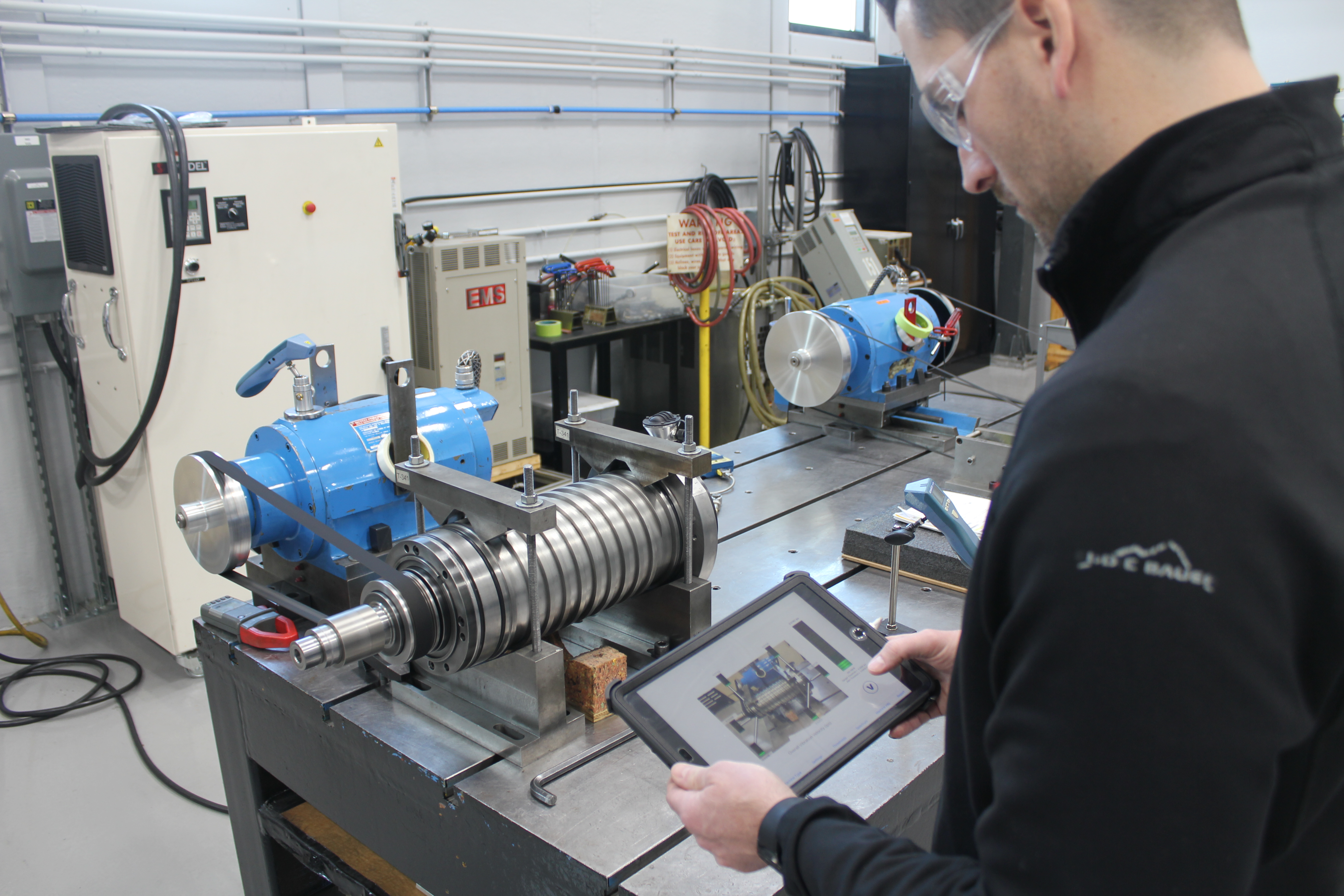

Our team combines extensive engineering knowledge with the latest diagnostic tools to repair and rebuild thousands of spindles annually. Our proven processes and techniques deliver rapid, dependable results and keep your operations running smoothly.

Our comprehensive process ensures long-lasting results and optimal spindle performance:

We carefully disassemble the spindle and check for damaged parts and components, wear and tear, and other signs of damage. We will also identify the causes of the issues to help us select the most practical repair methods.

Our team will clean and inspect the spindle’s components. We’ll machine and replace parts as needed to restore critical tolerances and maximize performance.

Our technicians will reassemble the spindle, add new or refurbished components as needed, and perform precision balancing to keep it operating smoothly.

We will test the repaired spindle to verify that it meets or exceeds OEM standards. We’ll also certify and document our work.

Keep your spindles on the job and maximize their service life with expert repairs and refurbishments from Setco. Take the next step and contact us to request additional information or discuss your project with our team today.