Our technicians will take your spindle apart to clean its parts and determine the cause of failure.

SNK America, Inc. is a well-known manufacturer of spindles and machine tools. Their spindles use Japanese designs and manufacturing, making them ideal for grinding, turning, cutting, and other applications. When SNK spindles become damaged or worn, immediate repairs are necessary to keep productivity and efficiency high.

Setco is a prominent and trusted independent spindle rebuilder with extensive experience repairing SNK spindles. With our professional services, you can restore your nonconforming spindles to service right away.

Spindles are essential parts of machine tools that hold and turn the workpiece. Spindles that conform to OEM specs and have no damage can deliver accurate performance with every use. For your company, these spindles can help your team increase productivity and save money on maintenance expenses.

During our extensive repair experience, we have seen many of the issues that commonly impact the technical components of SNK spindles, including:

Setco understands the importance of SNK spindles in your manufacturing processes. We have the training, equipment, and tools to ensure your spindle can continue to support your operation.

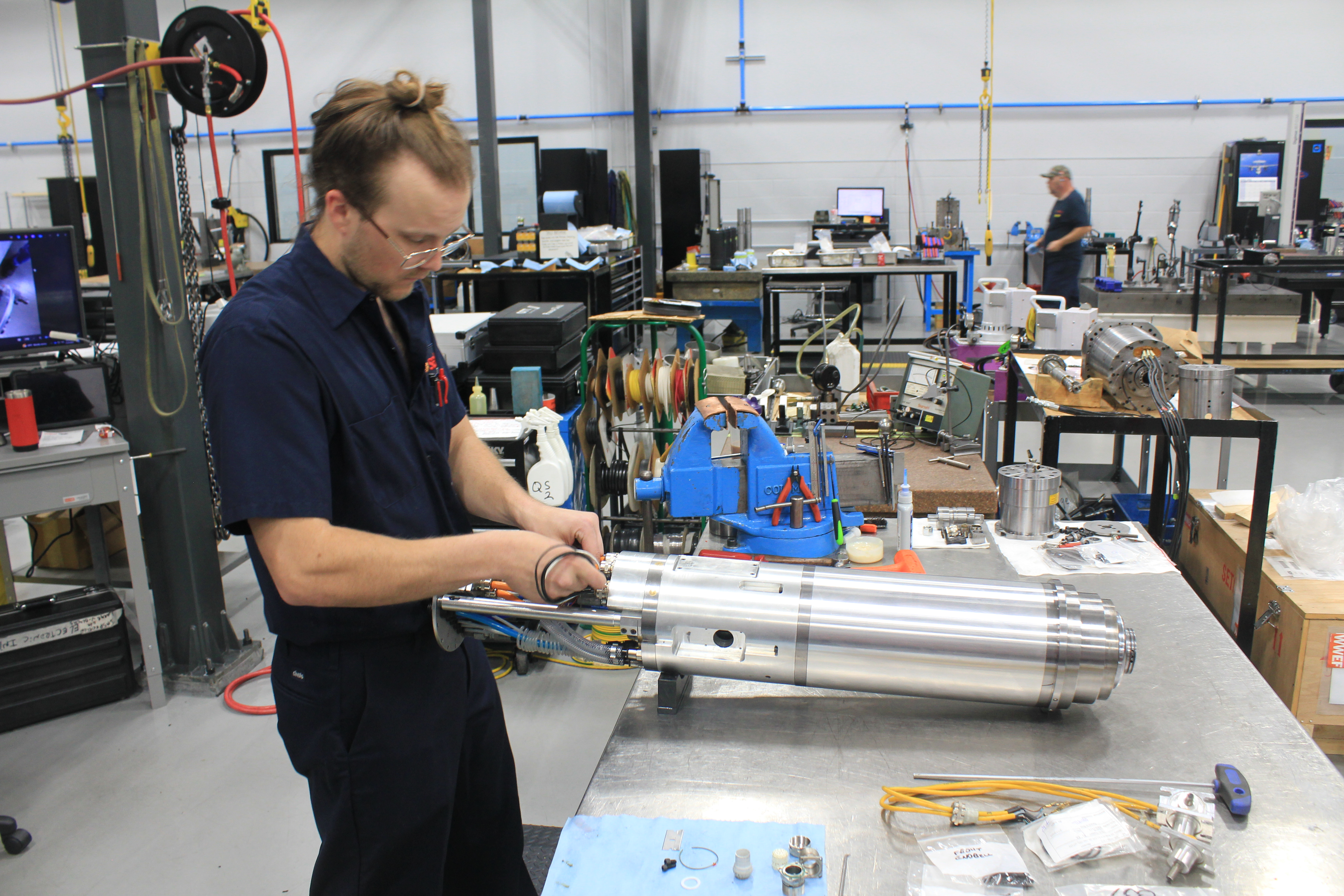

Setco’s spindle repair process is thorough and meticulous to identify the nonconformities with your spindle and address them right away. We repair more than 14,000 spindles yearly, including these SNK spindle model types:

The steps include:

Our technicians will take your spindle apart to clean its parts and determine the cause of failure.

We’ll inspect the components for signs of wear and damage. The parts we’ll assess include:

After considering the reasons for failure and damage, we’ll generate a firm price quote, which is free of charge in most cases. If you change your mind, we’ll return your spindle right away.

Our technicians will replace or condition parts to restore your spindle to its original specs. We can:

We’ll reassemble, balance, and test your spindle under controlled conditions, storing baseline vibration and testing data for future reference.

After repairs and testing are complete, we’ll send you:

Setco is your trusted partner in spindle rebuilds and repairs. We have served many industries, from aerospace to food processing, by identifying spindle issues and making immediate repairs. In addition to professional services, we provide dedicated customer service and warranty protection. Learn more about how we can repair your spindles by calling a Setco service center or contacting us online.