We’ll disassemble and clean your spindle then evaluate it to identify the reason for failure.

Toyoda Machinery has manufactured spindles for cutting and material removal since 1941. Now known as JTEKT, Toyoda spindles are used in automotive parts manufacturing and many other industries worldwide. Setco has extensive experience repairing and building Toyoda spindles. With our professional technicians and fully equipped service centers, we can restore your spindle to operational service and OEM specifications.

Setco knows that issues with spindles can impact their performance and your efficiency. We are equipped to identify and fix any problem your spindle has. Some of the most common issues Toyoda spindles experience include:

Setco is the largest independent spindle rebuilder globally, with 100 years of experience in the machine tool industry. We rebuild or repair over 14,000 spindles every year, over 350 OEM brands including Toyoda. Setco can repair many types of Toyoda spindles, including:

With our extensive experience with spindle types and problems, we have likely seen the issue affecting your spindle before and have an immediate solution ready to deploy. All of our rebuilds are backed by a warranty for your peace of mind.

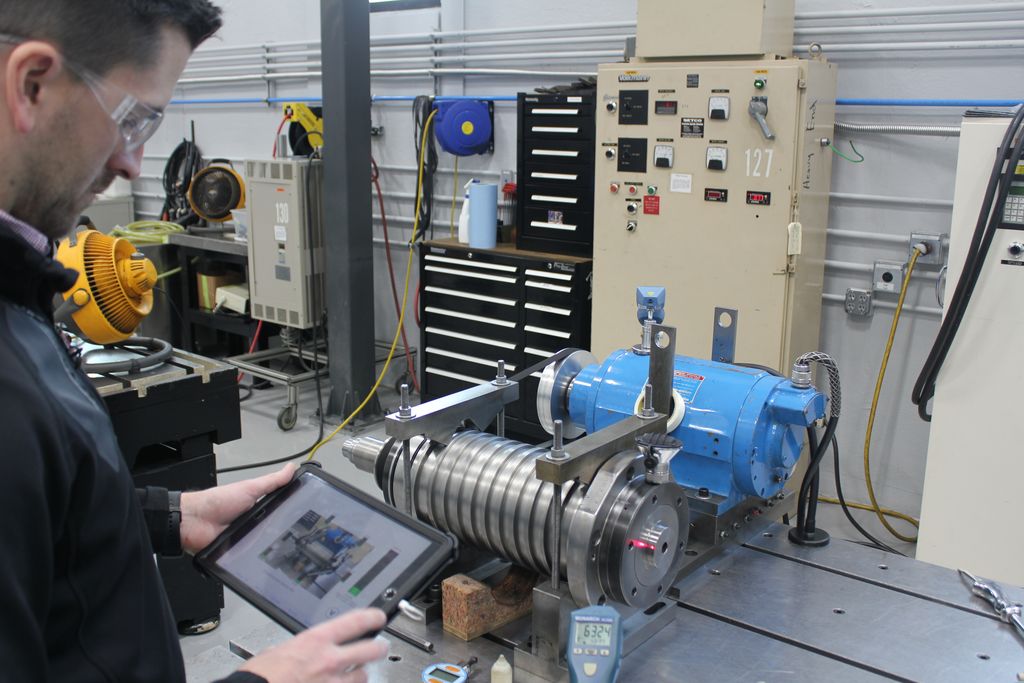

Setco uses a proven spindle rebuild process that returns components to like-new performance. Our process involves these steps:

We’ll disassemble and clean your spindle then evaluate it to identify the reason for failure.

We’ll complete a full inspection of the bearing journals, spacers, bore, caps, shoulders, bushings, and other critical components for signs of wear and damage.

Our technicians will create a firm price quote based on the repairs your spindle needs. Our quotes are without obligation and free of charge in most cases.

After you accept our quote, we’ll begin service right away. We’ll replace or recondition the spindle parts to OEM specs to restore its operating performance. Some of the many repairs we can complete include sleeving and machining housings, replacing spindle bearings, replacing drawbar seals and springs, checking components for balance, and checking electrical parts.

Your spindle will be reassembled, run off, and precision-balanced to make it ready for service. Setco stores testing data electronically by serial number for future reference.

We’ll return your spindle to you, along with full documentation, certification, and a written warranty.

Setco is the largest independent spindle rebuilder globally, with 100 years of experience in the machine tool industry. We rebuild or repair over 14,000 spindles every year, over 350 OEM brands including Toyoda. Setco can repair many types of Toyoda spindles, including:

With our extensive experience with spindle types and problems, we have likely seen the issue affecting your spindle before and have an immediate solution ready to deploy. All of our rebuilds are backed by a warranty for your peace of mind.

When your company needs professional repairs for your Toyoda spindles, choose Setco. We provide quick and professional repair and rebuild services alongside dedicated customer service. Call a Setco location near you or contact us online to learn more about our repair services.