Spindles undergo complete disassembly, thorough cleaning, and comprehensive failure analysis to isolate problems and determine the root cause of the issue.

Spindles are critical for various manufacturing processes, from milling and drilling to boring, routing, and grinding. These devices power belt-driven systems, motorized units, and direct-drive configurations found in many of today’s top machine shops. Keeping a spindle in peak operating condition is vital for maintaining high efficiency, preventing downtime, and achieving tight tolerances.

With decades of expertise in spindle repair, Setco specializes in repairing spindles from Anderson and many other leading brands. Our technicians are highly familiar with these devices and have the skills to restore these units to like-new condition.

Spindles enable CNC machines to perform complex cutting operations for various industries, including aerospace, automotive, robotics, stone cutting, and more. When spindle performance declines, it can affect a workpiece’s surface finish, dimensional accuracy, and overall quality. Spindle failures can halt an entire production line with costly delays and downtime.

Spindle assemblies must maintain perfect balance while withstanding high cutting forces, thermal stress, and hours of non-stop production. Setco provides comprehensive repair solutions that address these challenges, ensuring Anderson spindles continue to deliver reliable performance.

As the world’s largest independent spindle rebuilder, Setco delivers many benefits to each spindle repair project we undertake, including:

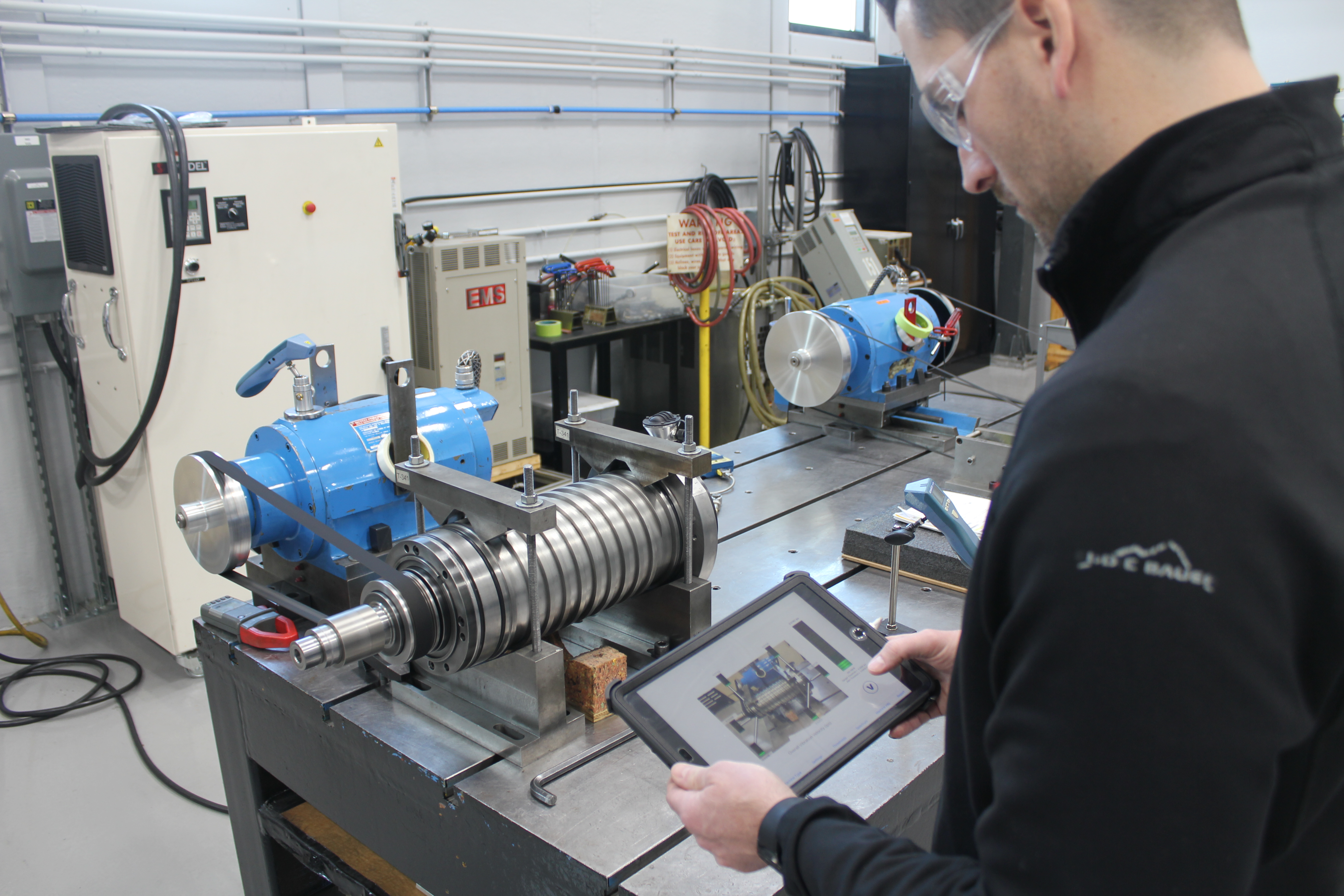

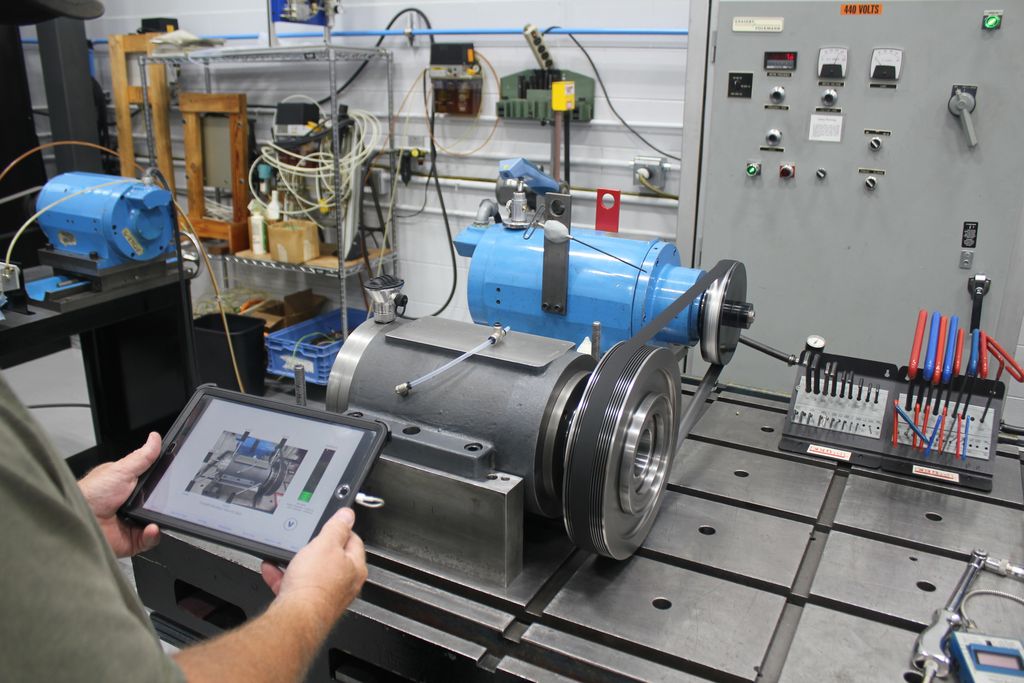

At Setco, we use a methodical approach for each rebuild, starting with a failure-mode evaluation and ending with a run-off under controlled conditions. Our process includes:

Spindles undergo complete disassembly, thorough cleaning, and comprehensive failure analysis to isolate problems and determine the root cause of the issue.

We examine each spindle component — including bearings, shoulders, caps, bushings, and spacers — for wear patterns, damage, and dimensional accuracy.

We provide free, detailed quotes for each repair project with no hidden costs.

We repair or replace each spindle component to ensure like-new performance. Services include housing sleeving and machining, bearing replacement, shaft chroming and regrinding, seal replacement, and new electrical components.

Spindles undergo reassembly, balancing, and full operational testing under controlled conditions until thermal stabilization occurs at maximum speeds. Testing data and vibration measurements are electronically archived by the spindle’s serial number.

Completed rebuilds undergo final quality verification before return shipment with documentation and certification. Every rebuild includes written warranty coverage.

Anderson spindle rebuilds require expertise and proven processes based on decades of knowledge and experience. Setco’s comprehensive multi-step approach ensures these critical components return to service with extended operational life. Call 877-545-3087 or contact us online today with questions or to request additional information.