Our team carefully assesses and disassembles each spindle to determine the type and extent of any damage or other potential issues. We’ll use various techniques to identify the cause of any problems.

Brother spindles can add significant value to CNC machining and other manufacturing processes — but only if they’re performing at their best. At Setco, the world’s largest independent spindle repairer and rebuilder, we know what it takes to ensure reliable Brother spindle results.

We have the expertise, resources, and facilities to handle any minor or complex Brother spindle repair, or rebuild project quickly and affordably. Our team can restore your spindles to meet or exceed their original OEM specifications, enabling you to optimize your manufacturing operations.

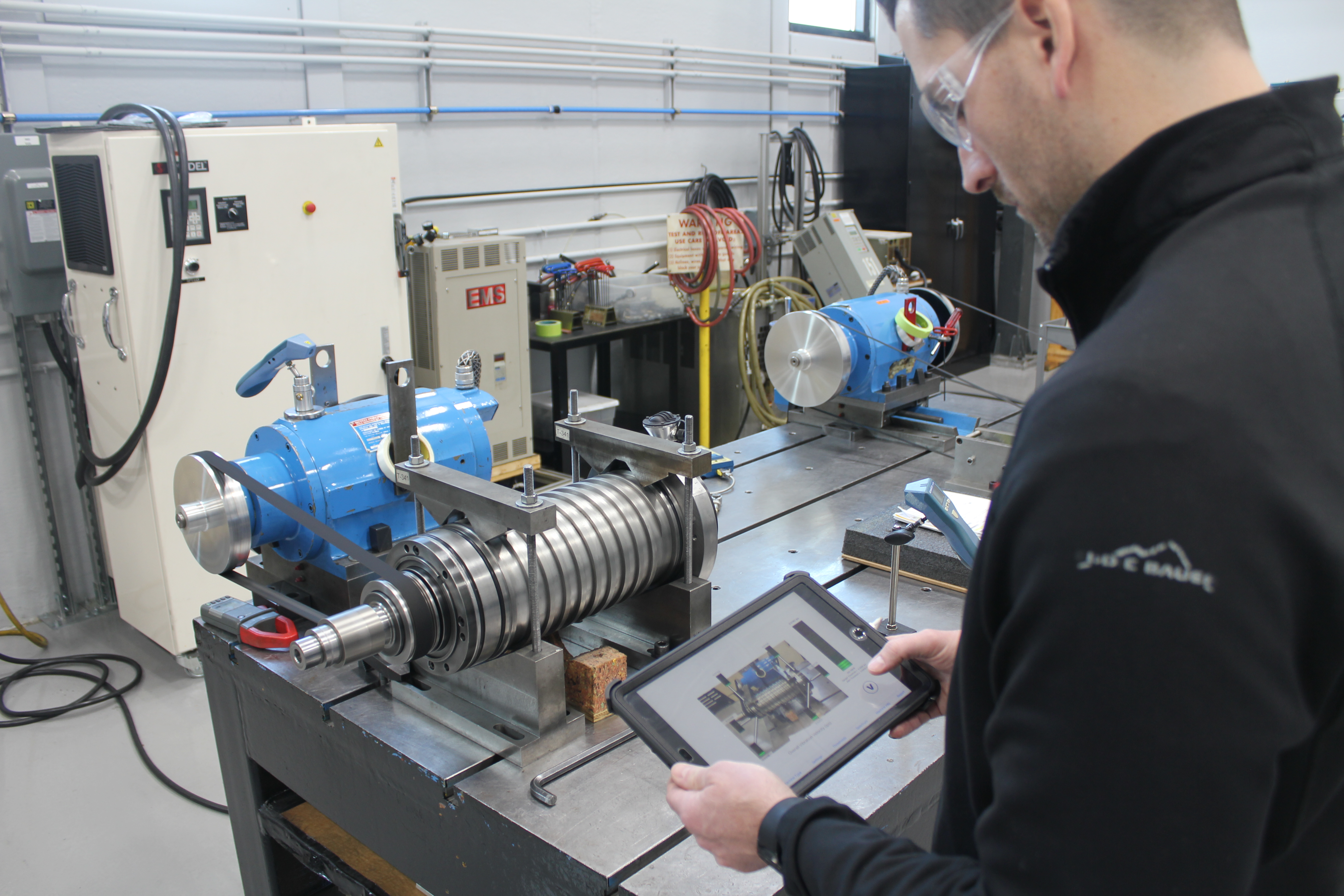

We employ various innovative techniques, including chroming, laser cladding, and regrinding, when repairing and refurbishing spindles to deliver dependable, long-lasting results. Our predictive maintenance and IoT-enabled diagnostics help manufacturers anticipate issues before they lead to costly downtime.

We offer different levels of spindle service to meet the needs and expectations of every Brother spindle user. Our standard offering provides comprehensive repairs and rebuilds requiring normal lead times, making it the best choice for non-emergency situations. Rapid repairs are also available for customers who need faster project turnaround times.

If you’re seeking a spindle condition analysis instead of a repair or rebuild, our test and run service level will provide detailed feedback regarding potential issues and corrections to help you make more informed decisions.

The telltale signs of spindle problems include:

We employ various innovative techniques, including chroming, laser cladding, and regrinding, when repairing and refurbishing spindles to deliver dependable, long-lasting results. Our predictive maintenance and IoT-enabled diagnostics help manufacturers anticipate issues before they lead to costly downtime.

We offer different levels of spindle service to meet the needs and expectations of every Brother spindle user. Our standard offering provides comprehensive repairs and rebuilds requiring normal lead times, making it the best choice for non-emergency situations. Rapid repairs are also available for customers who need faster project turnaround times.

If you’re seeking a spindle condition analysis instead of a repair or rebuild, our test and run service level will provide detailed feedback regarding potential issues and corrections to help you make more informed decisions.

Our time-tested repair process focuses on precision and thoroughness to achieve the best results for every project:

Our team carefully assesses and disassembles each spindle to determine the type and extent of any damage or other potential issues. We’ll use various techniques to identify the cause of any problems.

We’ll clean the components and check them for geometric accuracy. Our techs will replace damaged parts as needed to restore critical tolerances.

We’ll reassemble the spindle with premium-grade parts and conduct balancing to ensure reliable long-term performance.

Every repaired spindle undergoes rigorous testing to confirm it meets or exceeds OEM performance standards. We will provide comprehensive documentation and certification for your records.

We’ve designed the Brother spindle repair process to restore your equipment to peak performance, allowing you to support your manufacturing goals with confidence and gain more peace of mind.

Setco has been in the machine tool industry for over 100 years. We repair or manufacture more than 14,000 spindles annually, including many Brother products. Our ISO 9001:2015-certified facilities and extensive global service center network enable us to deliver prompt, reliable repair and rebuild solutions, maximizing uptime and helping you stay on schedule with your projects.

Contact Setco today to learn more about our Brother spindle repair and rebuild capabilities. You can also share information about your project and submit any questions you may have.