Technicians complete a full visual and functional inspection, including testing for runout vibration and noise. They use OEM specs as a baseline for their analysis.

At Setco, we have the knowledge necessary to repair HOMAG spindles. We are familiar with the typical specifications and the repair needs of this manufacturer’s components, including precision alignment and balancing. We complete repairs efficiently to minimize downtime. Our in-depth repair process helps enhance operations for smoother performance.

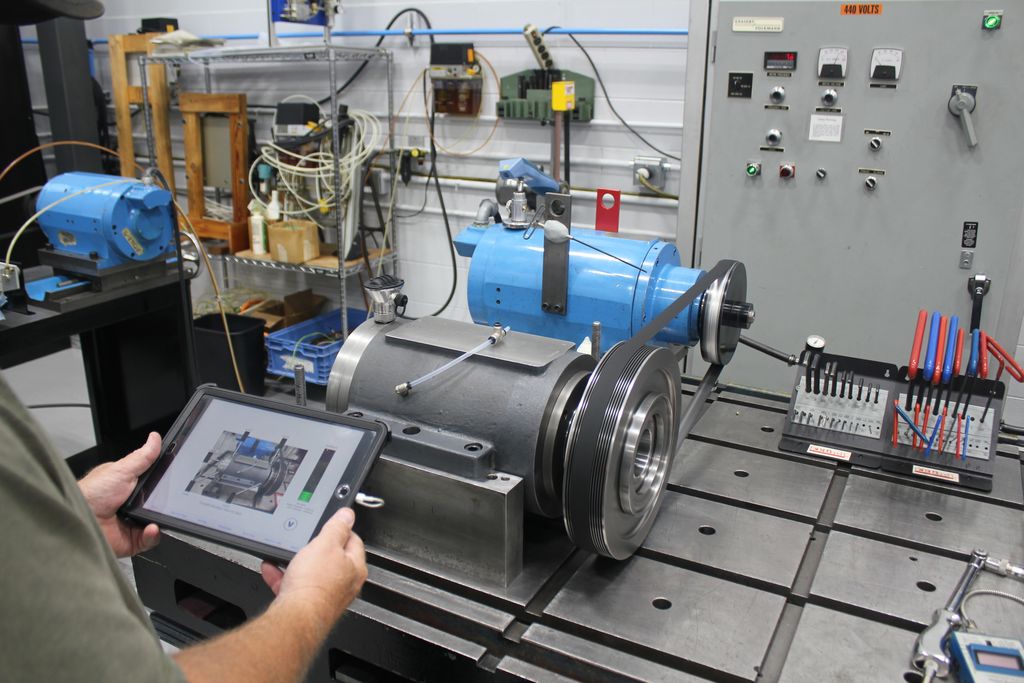

See the difference quality makes. Our before and after photos show the care and precision that go into every HOMAG spindle repair. From damaged or worn components to fully restored, like-new condition — we bring your spindle back to peak performance, helping you avoid costly downtime and get back to production faster.

We have over 100 years of experience in the machine tool industry and hold an ISO 9001:2015 certificate for our quality management system. Our extensive inventory of OEM and high-quality parts enables us to maintain a stock of necessary components for various types of spindle repairs. We perform all work in-house, including diagnostics and engineering. These capabilities enable manufacturers to benefit from accurate, efficient repairs.

Turn to us for repairs to get production lines up and running quickly. Our technicians have expertise with manufacturers, including HOMAG. We can work with the various types of spindles from this manufacturer, including: milling, router, drilling, boring, belt-driven, motorized, direct-drive, and gear-driven varieties. We deliver repairs that match or exceed OEM specifications and follow a detailed process for consistency:

Technicians complete a full visual and functional inspection, including testing for runout vibration and noise. They use OEM specs as a baseline for their analysis.

Once we’ve assessed the spindle, we can share the necessary repairs and provide a cost estimate. Based on these details, manufacturers can decide if we’re the right fit.

As the repairs begin, our technicians disassemble the spindle, carefully labeling and documenting all components. They take special care of sensitive components, such as: the spindle shaft, bearing seats, and tool interface.

We decide which parts need replacement based on wear, corrosion, or damage. Technicians choose OEM parts or higher-quality replacements.

Our team reassembles the spindle and uses precision measurements to check for details like: shaft straightness, bearing fits, and tool interface alignment.

We perform dynamic balancing at operational speeds and test all key functions. Once we’ve completed testing, we carefully package and return the spindle with detailed reports.

We have locations across continents in the United States, China, Taiwan, and India. These facilities offer nearby access for those seeking service, products, or repairs. Our convenient locations also enable us to provide faster turnarounds for those seeking emergency services.

We serve a diverse range of industries with our spindle repair services, enabling us to understand the unique needs of each one. We understand the speed, precision, and reliability required in industries such as: woodworking, cabinetry, and furniture, which often utilize HOMAG spindles. Our team also collaborates with other manufacturers utilizing these spindles, including those in the automotive, food processing, medical, and transportation industries.

Maintain efficient, high-quality production with help from Setco. We offer fast and precision repairs to get operations back up and running. Contact us online to discuss an evaluation and repairs for HOMAG spindles.