Technicians disassemble the spindle and clean each component to expose wear patterns, damage, and contamination. We examine shaft journals, bearing races, housing bores, and seal surfaces to identify the causes of failure.

Mitsubishi Electric CNC has been designing and manufacturing machine tools and control systems for over 50 years, serving a wide range of industries. The company produces milling machines, turning centers, tapping machines, and multi-axis machining centers that rely on their SJ-Series spindle motors and MDS-Series drive units for precision work. These systems handle operations from high-speed milling to heavy-duty turning, using spindle technology designed for accuracy and torque control.

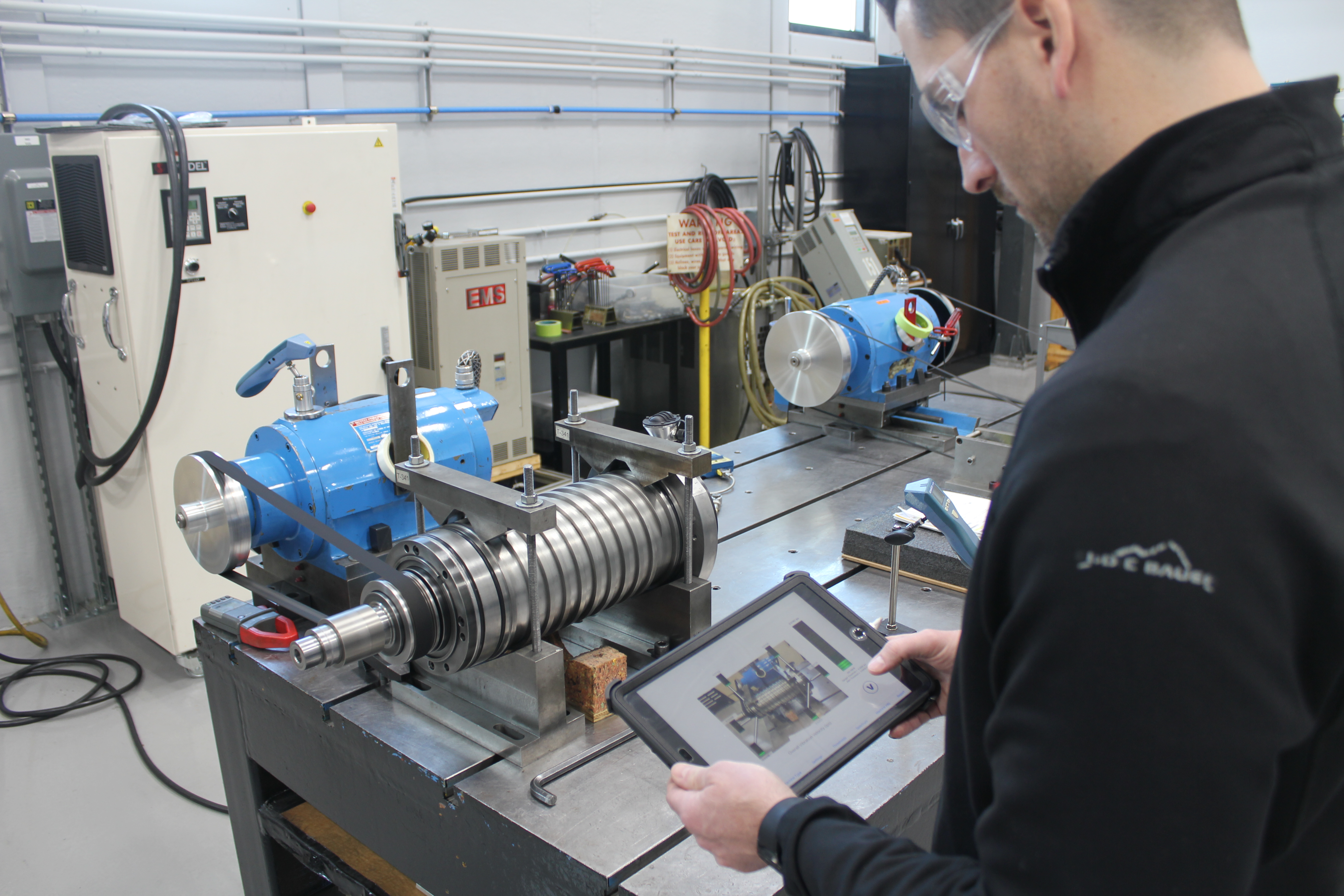

Setco repairs Mitsubishi spindles to meet original manufacturer specifications.

When Mitsubishi spindles develop problems, production quality and efficiency suffer. Bearing wear creates vibration that affects surface finish and dimensional accuracy. Seal failures allow coolant contamination into bearing assemblies, accelerating damage and leading to overheating.

Tool holders that won’t release properly or cutting tools that chatter during operation often indicate taper wear or spindle runout problems. Temperature spikes during normal operation signal inadequate lubrication or bearing preload issues. Unusual noise during spindle acceleration or deceleration points to bearing damage or motor problems that need diagnosis before complete failure occurs.

Addressing these issues immediately can be the difference between staying productive and dealing with lengthy periods of equipment downtime.

Setco’s detailed process for spindle repair provides detailed attention at every stage:

Technicians disassemble the spindle and clean each component to expose wear patterns, damage, and contamination. We examine shaft journals, bearing races, housing bores, and seal surfaces to identify the causes of failure.

Customers receive detailed estimates that outline the required work and costs, with no hidden charges. The quotes spell out exactly what needs repair before any work begins.

Worn components are replaced with high-quality parts that meet original OEM specifications. We regrind and refinish shafts, machine the housings, install new bearings with proper preload, and replace all seals and electrical components.

Rebuilt spindles run at full operating speeds with thermal stabilization while we monitor vibration levels and record performance data. Testing continues until the spindle operates within specification at maximum rated speeds. We record all measurements according to the spindle serial number.

Completed spindles receive final inspection and ship with parts lists, testing documentation, and warranty coverage.

We’ve designed the Brother spindle repair process to restore your equipment to peak performance, allowing you to support your manufacturing goals with confidence and gain more peace of mind.

Setco delivers exceptional value and reliability in every spindle repair through benefits like:

Find out more about our capabilities to restore Mitsubishi spindles to peak condition with fast lead times. Contact us online or call today with questions or to request a quote.